Notified by email when this product becomes available

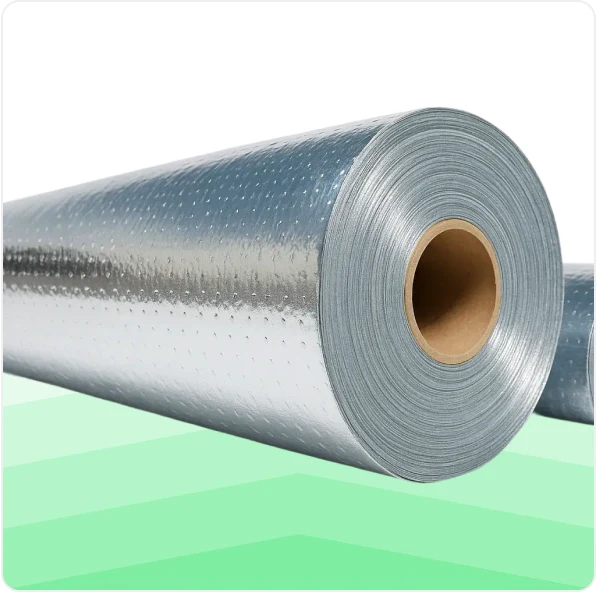

SmartTAPE - Reflective Aluminum..

- Product Details

- Materials

- Application

- Technical Specs

- Shipping Info

FAQ

Welcome to store

Free Shipping

60 days money back

10 years warranty